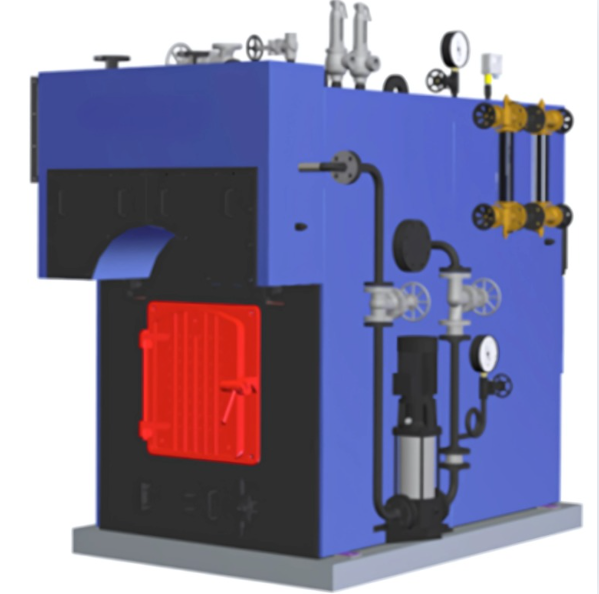

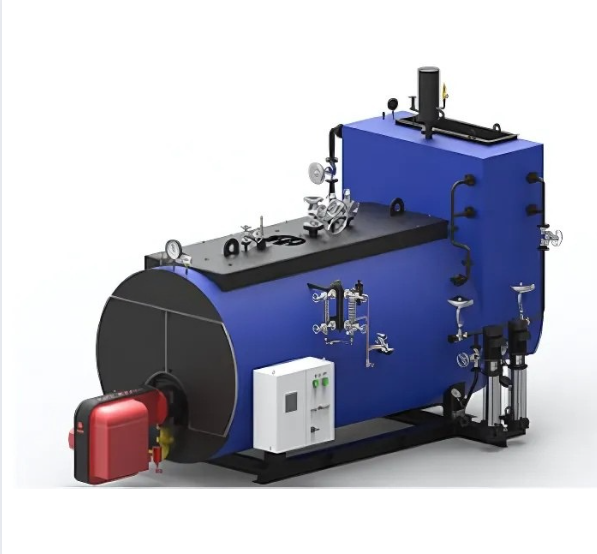

| Modular Boiler

Capacity : 1.5 to 10TPH

Firing : Manual/Automatic

Combustor : Stationary Grate/Bubbling Bed/Reciprocating Grate

Pressure : 10.54/17.5/24 Kg/Cm2g

(COMBLOC IMAGE)

More Info

Application:

Steam Boiler for Process Heating

Product Info

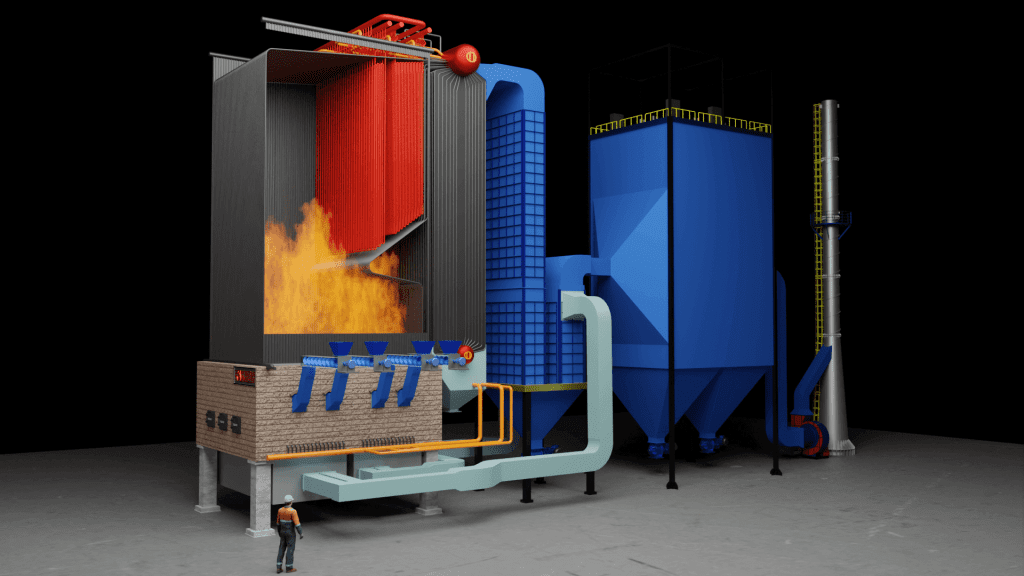

So far, the two major options for a solid fuel-fired steam boiler were the Integrated Furnace Boiler and the conventional Hybrid Boiler. This meant that the choice boiled down to the reduced site work and better response to the load of the Integrated Furnace Boiler, versus the promise of higher efficiency and fuel flexibility of the conventional Hybrid Boiler. What remained unexplored was the ideal solution -the best of both these designs packed into one boiler. But not anymore. Because this boiler is an amalgam of the best of these two designs and represents the future of packaged, multi-fuel-fired steam boilers. This robust product is a highly compact, efficient, plug-and-play packaged boiler, designed to meet your steam requirements today and tomorrow.

Product Feature:

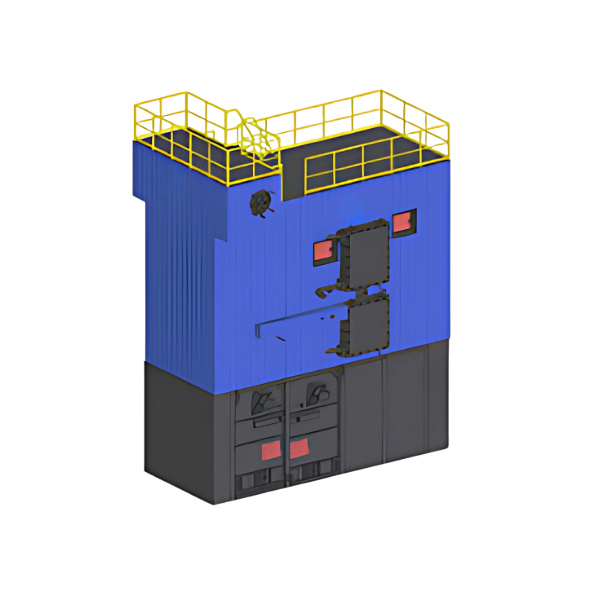

Compact, skid-mounted and modular construction – up to 40% reduction in footprint

Pre-insulated and factory assembled – up to 80% reduction in site work

The flexibility of fuels (Biomass/ Fossil) and combustors

Quick startup and better response to load fluctuations

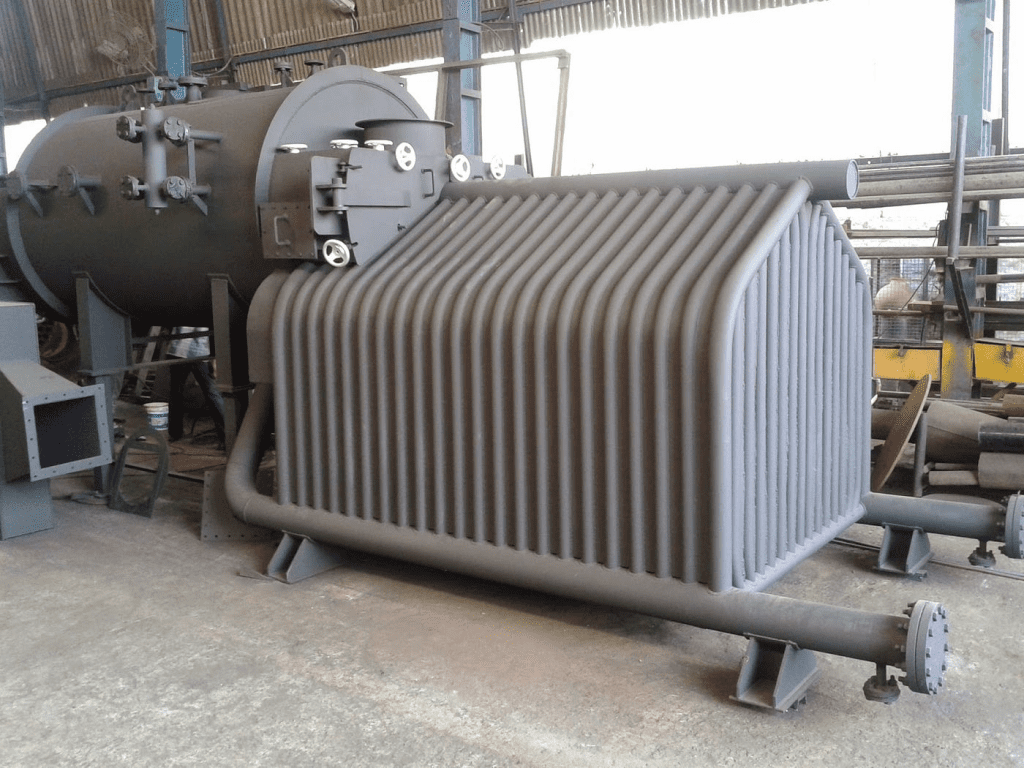

Multi-pass hybrid construction with high combustion volume – better efficiency

Easy ash removal and better accessibility for maintenance

|