Energising Processes Worldwide

Welcome to Spenomatic Kenya Ltd., your trusted partner in delivering high-quality industrial equipment and accessories designed to meet the demands of a wide range of industries. Whether you’re in the natural gas, power, petroleum, pharmaceutical, chemical, or fertilizer industry, our comprehensive solutions are tailored to enhance the efficiency and reliability of your operations. From advanced isolation valves and bellow seal valves to specialized steam traps, pressure reduction valves, and condensate pumps, our products are engineered to perform seamlessly in critical systems including hot/cold water, thermal oil, natural gas, steam, and refrigeration. Explore our offerings and discover how Spenomatic Kenya Ltd. can help drive your industrial success.

Ultimate Solutions For

Thermal oil Systems

Steam Systems

Hot & Cold Water Systems

Natural Gas

Refrigeration Systems

Pump Trap System

- Click on labelled components to view more details

Features :

A complete skid mounted package unit with receiver, motive steam

line and check valve at outlet

Pumps condensate at 100 Deg. C. plus

Works on steam/air

Recovers 50 to 50,000 kg/hr of condensate

Benefits:

Lower cost of operation and higher amount of heat recovered, compared to centrifugal pumps.

High feed water temperature can be achieved which eliminates the use of water treatment chemicals to

drive off the dissolved gases

Industrial Isolation Valves

Ball Valve

Technical specification

Design standard: ASME B16.34, API 608, API 6D

Fire safe: API 607, ISO 10497

Face to face dimension: ASME B16.10

Flanged ends: ASME B16.5, ASME B16.47

BW ends: ASME B16.25 Test & inspection: API 598, API 6D

ANSI Gate Valve

Technical specification

Design standard: BS 1873, ASME B16.34

Face to face dimension: ASME B16.10

Flanged ends: ASME B16.5, ASME B16.25

Test & inspection: API 598, API 6D

Forged Gate Globe Check Valve

Technical specification

Design standard: ASME B16.34, API 602, BS 5352, ISO 15761

Face to face dimension: As per manufacturer’s standard

Ends: ASME B16.5, ASME B16.25, ASME B1.20.1, ASME B16.11 Test & inspection: API 598, ISO 5208

Bellow Seal Valve

Technical specification:

Design standard: 3356

Face to face dimension: 3202

Flanged ends: 2543-2545

Test & inspection: 3230

Applications:

Hot oil system, steam system, hot and cold water system etc

Advantages

1. Bellow seal element. The key part of bellow sealed globe valves is mental bellow. It is the connection between cover and stem with automatic roll welding. The mental bellow can keep the stem part no leakage.

2. Benefit from the con and streamline shape design, the disc has a reliable seal and longer service life.

3. Double seal design (bellows + packing). Bellow and packing can protect against leakage and provide a excellent seal.

4. Grease nipple. It can direct lubricate the stem, nut and sleeve.

5. Size above DN150 with triangle position device. It can protect internal parts from shaking, less noise and more tensile strength.

6. Different disc design for different work condition, regulating disc, globe-check disc, soft seal disc etc.

7. Ergonomic hand wheel. It provide longer service life and easier operation.

Types:

ANSI Bellow Globe Valve

Angle Type Bellow Globe Valve

Y Type Bellow Globe Valve

Y Type Bellow Globe Valve

Pipe Line Anciliaries

Y-type Strainer

Design standard: 3356

Face to face dimension: 3202

Flanged ends: 2543-2545

Test & inspection: 3230

Hot oil system, steam system, hot and cold water system etc.

Advantages:

1. Y type strainer is used to separate the impurity of media. It can protect other equipment for a regular service.

2. Stainless steel filter traps make a better performance and corrosion-resistance.

3. Maintenance is easy. All you need is just to clean the filter traps.

Lift / Wafer Check Valve

Design standard: 3356

Face to face dimension: 3202

Flanged ends: 2543-2545

Test & inspection: 3230

Hot oil system, steam system, hot and cold water system etc.

1. Lift check valve is self-sealing valve. The disc can be acted to the flow which can avoid against the media flow back.

2. The disc with spring can keep the valve work in any direction.

3. Reasonable structure, reliable sealing, excellent performance and attractive appearance.

Sight Glass

Body : Ductile Iron GGG 40.3

Cover : Ductile Iron GGG 40.3

Internals and float : Stainless Steel AISI 304

Connection Types: Flanged and threaded

Can be used vertically as the inlet to stay up the top and the outlet to remain at the bottom. It can also be installed horizontally from right to the left or opposite way.

When condensate reaches the steam trap, the float rises and open the main valve and discharges the condensate. As soon as the condensate discharge is completed and the steam reached into the trap, the float goes down and closes the valve. Condensate level in SK55L can be seen through the sight glass.

Safety Valve

Design standard: 3320

Face to face dimension: 3202

Flanged ends: 2543-2545

Test & inspection: 3230

Hot oil system, steam system, hot and cold water system etc.

Installed in the commutation of the pipeline to reduce the welding of the pipeline.

Pipe Line Anciliaries

Thermodynamic Steam Traps

Installation at super heated steam tempeture. High resistance against water hammer. Easy maintenance. Discharge condensate close to steam saturation temperature.

Main steam lines,Turbines, Marine Applications, Presses

DN15-25 1/2″-1″

40/42bar

Thermostatic Steam Traps

Reducing flash steam losses. Operation under back pressure more than 80% of inlet pressure. High resistance against water hammer. Easy maintenance.

Tracing Lines, Irons Heating, Equipment, Presses

DN15-100 1/2″-4″

21/32 bar

200 – 250 °C

Bimetallic Steam Traps

Reducing flash steam losses. Energy Saving. Good air venting. High resistance against water hammer.

Tracing Lines, Turbines, Marine applications, Presses, Ovens

DN15-50

1/2″-2″

32 bar

Inverted Bucket

Assured operation and durability. No air troubles. Easy maintenance. No need for seperate strainer

Tanks, Pans, Heat Exchangers, Drying Cylinders, Ovens

DN15-25

1/2″-1″

16 bar

Ball Float

High discharge capacity. Air venting Maximum heat transfer thanks to constant discharge. Installation both vertically and horizontally

Heat Exchangers, Oil tanks, Evaporaters, Fuel-oil tanks, Drying Cylinders, Ovens

DN15-50

1/2″-2″

16/25 bar

Mechanical Pressure Reducing Valves

Pilot operated Pressure Reducing valve

Design standard: GB12244

Flanged ends: DIN

Test & inspection: GB-12244-46

Hot oil system, steam system, hot and cold water system etc.

1. Especially suitable for steam and water.

2. Max inlet pressure: 16 bar, 25 bar.

3. Outlet pressure(Springs pressure setting range): Yellow-1-3bar, Blue-2-8bar, Red-7-12bar.

4. Diameter: 15-200mm.

5. Media temperature: 0-285 degree C.

6. Max rate inlet pressure/outlet pressure: 10:1.

7. DIN, ANSI, GB.

Self-Acting Pressure reducing Valve

Diaphragm-controlled spring-loaded and balanced proportional control valve for a broad selection of universal applications. The outlet pressure required is balanced across the control unit by the force of the valve spring (set pressure). As the outlet pressure rises above the set pressure using the adjusting screw, the valve cone moves around towards the seat and the volume of media is reduced. As the outlet pressure drops, the valve control orifice increases; when the pipeline is depressurised, the valve is open. Rotating the adjusting screw clockwise increases the set outlet pressure.

Control Valves

Punematic Actuators

Multi-spring, compact actuators.

Rotary diaphragm with good enhancing

features.

Can choose a different spring closing force.

Can be equipped with emergency handwheel.

Design standard: DIN.ANSI, GB

Face to face dimension: DIN, ANSI, GB

Flanged ends: DIN, ANSI, GB

Test & inspection: DIN3230, API 598

Hot oil system, steam system, hot and cold water system etc.

Electric Actuator Premio

To use synchronous motor to control precisely. With standard 2 torque switch and 1 limit switch. To adopt technology sealed electronic components and it has good shock resistance. High protection class Lp65. Be connected with various types of system.

High strength body and applies to every high load condition. Long distance design and control of high precision, it can be up to 50:1.

Provide a variety of forms of stem seal. Maintenance free. Optional threaded seat. It can reduce KVS value, which can up to 5 times.

With standard travel indicator.

Optional bellow seal.

Optional V-type/squirrel-cage valve head.

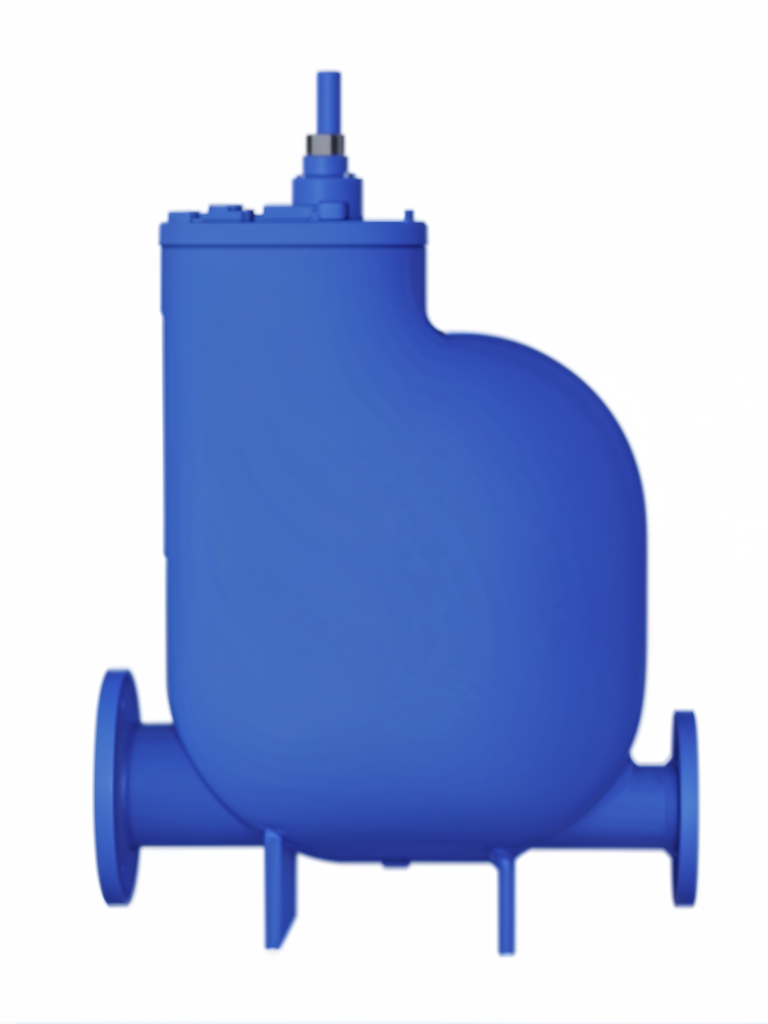

Condensate Pump

A mechanical power pump operates based on the principle of traps, utilizing steam, air, or other gases as power sources to transfer condensed water from low-pressure to high-pressure areas, or from a vacuum to normal pressure. This type of pump offers numerous advantages, including automatic control, resistance to cavitation, simple maintenance, no need for electricity, resistance to water hammer, large capacity, explosion-proof design, silent operation, and the ability to adjust the head based on the pressure of the driving steam or gas. Its unique capabilities make it ideal for use in steam systems for transporting condensed water and low-viscosity, non-volatile liquids.

Working Principle

- Inlet and Exhaust Process: Initially, the inlet check valve opens while the outlet check valve remains closed due to high back pressure. Water begins to enter the pump, causing the float to be in a low position. As the water level rises, the exhaust valve opens, and the float reaches its highest position, triggering the controller to switch to a neutral state.

- Inlet Steam (Gas) Drainage: Once the float reaches a high position, the controller activates, closing the exhaust valve and opening the power steam (or air) inlet. Steam is injected into the valve, pushing the condensate in the pump to a high-pressure area using steam pressure. During this process, the inlet check valve remains closed due to the high internal pressure. When the float drops to a low position, the controller switches again, closing the power steam inlet, opening the exhaust valve, and initiating the next cycle.

Performance Characteristics

- Non-Electric Drive: The pump is powered by steam or compressed air, making it explosion-proof, safe, and suitable for any environment.

- Compact Structure: It has no specific installation requirements and can operate normally even in open environments.

- Automatic Control: The water output is automatically adjusted based on the intake. As the volume of condensate increases, the working frequency accelerates; when it decreases, the frequency slows down. The pump stops when there is no condensate.

- Cavitation-Free Operation: It completely eliminates the cavitation issues found in electric pumps.

- Durable Construction: All internal parts are made of stainless steel, and special materials are used to ensure optimal performance and longevity.

Important Considerations

- It is recommended that the head height of the incoming fluid be at least 0.5 meters (measured from the pump cover). Please refer to the “Inlet Water Height Correction Factor” for guidance.

- The power steam inlet should be connected to RC1/2″.

- For normal operation, the saturated condensate must be flashed or condensed. In a closed system, ensure that the pressure difference and back pressure rate are sufficient for the pump trap to function properly.

- The standard configuration for the condensate inlet and outlet is a HG/T20592-2009 PN16 flange connection. If other standards such as ASME16.5 or JIS are required, please specify.

Get a free monthly magazine about systems, accessories, new updates and modifications, as well as advise on product selection and more.

An Award Winning Company

Established in 1998, SKL is a group of over 100 technocrats from diverse fields contributing in empowering in Africa in the energy and environment sector. Our vision is to become an intergrated Hub of very high-end technologies in the field of energy and environment,which leap frog our customers to world class standard in these areas.

Vision

Our vision is to become an integrated Hub of very high-end technologies in the field of energy and environment which leap frog our customers to a world class standard in these areas. Making it a permanently win-win position for our customers, suppliers and us.

Mission

At Spenomatic, our mission is to design and deliver innovative, cutting-edge technical products that enhance the lives of our customers. We believe that technology has the power to transform the way we work, live, and interact with the world around us. We strive to provide exceptional customer service, and to build long-term relationships with our customers.

Our Process

By partnering with global leaders in steam technology, we provide state-of-the-art equipment, including steam traps, control valves, condensate pumps, and heat exchangers. Each component is selected for its ability to enhance the overall steam system, ensuring seamless operation and minimal energy loss.