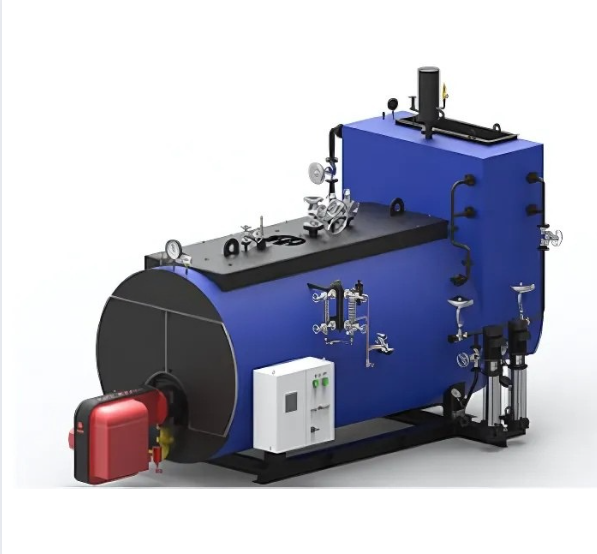

Boilers are essential in various industries, from providing heat to power plants to supporting manufacturing processes. However, traditional boilers face challenges like high energy consumption, maintenance costs, and environmental impact. Modern boiler technologies are solving these issues with innovative solutions that enhance efficiency, reduce costs, and minimize emissions.

Energy Efficiency Improvements

Modern boilers are designed for optimal energy efficiency. One significant advancement is condensing technology, which captures and reuses heat from exhaust gases, boosting overall efficiency. This process reduces energy waste and significantly lowers operating costs for businesses, helping them stay competitive while minimizing their environmental impact.

Another key innovation is the use of smart controls. These systems adjust boiler operation based on real-time demand, ensuring the system uses only the necessary amount of energy. This adaptability helps businesses cut down on energy waste and lowers their operational costs.

Lower Emissions for a Greener Future

Modern boilers are built to reduce harmful emissions. Advanced combustion technology allows them to burn fuel more efficiently, which reduces nitrogen oxides (NOx) and carbon dioxide (CO2) emissions. This is a step toward meeting stricter environmental regulations and contributing to a greener future.

Additionally, some modern boilers integrate renewable energy sources such as biomass or solar power. Biomass boilers, for example, use organic materials like wood pellets, helping to reduce reliance on fossil fuels and contributing to sustainability.

Reduced Maintenance and Operational Costs

Maintenance and repairs can be expensive for older boilers. Modern boilers are designed to be more reliable and long-lasting. The use of advanced materials and improved designs helps minimize wear and tear, leading to fewer breakdowns and longer equipment lifespans.

Self-diagnostic features are another common feature in modern boilers. These capabilities allow operators to detect issues early, reducing the need for frequent service calls and costly repairs. This proactive approach ensures reliable operation and reduces downtime.

Modular and Scalable Designs

Modern boiler systems now come in modular designs, allowing businesses to scale heating capacity as needed. Operators can easily adjust these systems to match changes in demand, ensuring efficient energy use without overloading the system.

Modular boilers suit businesses with fluctuating heating requirements. They provide flexibility and allow operators to expand or downsize setups as conditions change. This approach avoids oversizing, reduces energy waste, and cuts down on operational costs.

Benefits of Modular Boilers for Modern Businesses

Modular boilers offer several key benefits, particularly for businesses looking to enhance their energy efficiency and operational flexibility. Here are some of the main advantages:

- Scalability: As demand fluctuates, businesses can add or remove modules to meet their exact heating requirements. This ensures energy is used optimally, preventing over or underutilization of heating capacity.

- Energy Efficiency: Modular designs often operate more efficiently than traditional single-unit boilers. By allowing businesses to run only the necessary modules, they minimize energy waste and reduce operational costs.

- Reduced Capital Investment: Businesses no longer need to invest in large, expensive boiler systems that might be too large for their needs. Modular boilers allow companies to invest based on current demand while scaling as necessary.

- Quick Maintenance and Repairs: In case of a malfunction, businesses can isolate and repair individual modules, reducing downtime and maintaining continuity in the heating process. This modular approach enhances system reliability.

- Environmental Benefits: By optimizing energy use and reducing emissions, modular systems also contribute to a more sustainable energy model, aligning with companies’ environmental goals.

Smart Integration for Optimized Performance

Smart technology continues to transform how boilers operate. Many modern systems now feature sensors that track key performance metrics such as temperature, pressure, and fuel use. Operators can analyze this data in real time to fine-tune performance and address inefficiencies quickly.

By integrating with building management systems (BMS), these boilers offer centralized control over the entire heating infrastructure. Smart features enable automatic adjustments that maintain peak performance and minimize energy waste.

Spenomatic Kenya’s Contribution to Modern Boiler Technologies

At Spenomatic Kenya, we deliver innovative and energy-efficient boiler solutions for industries that demand reliable and sustainable systems. Our technologies feature cutting-edge designs and incorporate smart controls, optimized combustion, and modular scalability.

We tailor our solutions to each client’s unique requirements, whether it’s a large-scale manufacturing plant or a specialized industrial application. Our team stays focused on helping businesses reduce costs, minimize emissions, and increase operational efficiency with modern boiler technologies.

Conclusion

Modern boiler innovations are reshaping industries by enhancing energy efficiency, cutting emissions, and lowering long-term operational costs. These improvements help businesses remain competitive while meeting strict environmental standards. As smart and sustainable solutions gain momentum, modern boilers will continue driving industrial energy transformation.

At Spenomatic Kenya, we proudly lead this shift. We provide tailored, high-performance boiler systems designed to meet today’s industrial challenges. Our commitment to sustainability and efficiency empowers businesses to achieve long-term savings and meet environmental goals.

FAQs

1. What makes modern boilers more energy-efficient?

Modern boilers use technologies like condensing systems and smart controls that capture waste heat and adjust operations based on real-time demand, improving efficiency.

2. How do modern boilers reduce emissions?

They rely on advanced combustion systems that burn fuel more completely, reducing harmful emissions such as nitrogen oxides (NOx) and carbon dioxide (CO2).

3. Can modern boilers be scaled to meet changing needs?

Yes. Their modular designs let businesses scale systems up or down based on fluctuating demand, ensuring efficient energy use.

4. How does Spenomatic Kenya contribute to modern boiler solutions?

We offer tailored, high-efficiency boiler systems designed for specific industrial needs. Our solutions reduce both energy costs and environmental impact.

5. What are the long-term benefits of modern boiler technologies?

They reduce energy consumption, cut maintenance costs, and provide long-lasting performance—making them a smart, sustainable investment for industrial operations.