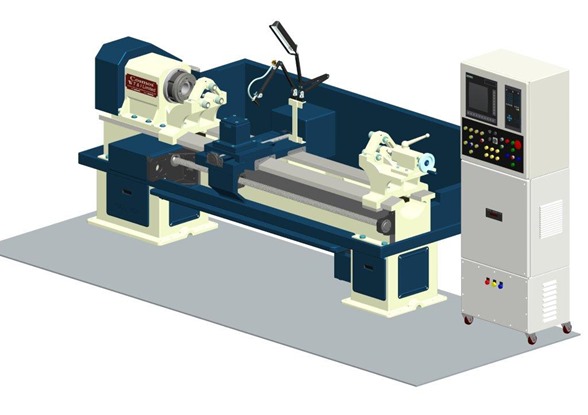

Specifically designed for the manufacture of orthodox teas, this modernized roller incorporates advanced features to enhance operational efficiency, durability, and tea quality. Engineered with precision, it meets the demands of the modern tea industry while maintaining the integrity of traditional orthodox tea production.

Key Features:

- Table:

- Constructed from mild steel plate mounted on a heavy-duty cast iron frame, lined with durable ‘Kithul’ wood.

- Optionally available with food-grade stainless steel plate for enhanced hygiene.

- Table frame circumference lined with hardwood for long-lasting performance.

- Cone:

- Available in Rettie or Keegal shapes, made from food-grade phosphor bronze.

- Optional materials include brass or gunmetal for specific processing needs.

- Battens:

- Crescent-shaped battens made from ‘Kithul’ wood or food-grade stainless steel.

- End/tips crafted from food-grade phosphor bronze, with optional brass or gunmetal materials.

- Pressure Plate:

- Food-grade stainless steel plate mounted on a heavy-duty cast iron frame, lined with hardwood.

- Electro-pneumatically controlled, fully programmable, with inching control for precision adjustments.

- Discharge Door:

- Electro-pneumatically controlled and programmable, featuring an inching control mechanism and differential control valve for variable piston speed.

- Automation:

- Fully automatic and programmable control panel with a user-friendly touch-screen HMI and PLC system.

- Includes a manual by-pass option for operational flexibility.

- Equipped with reliable pneumatic cylinders, precision flow-control, solenoid valves, FRL unit, and pressure gauges for optimal performance.

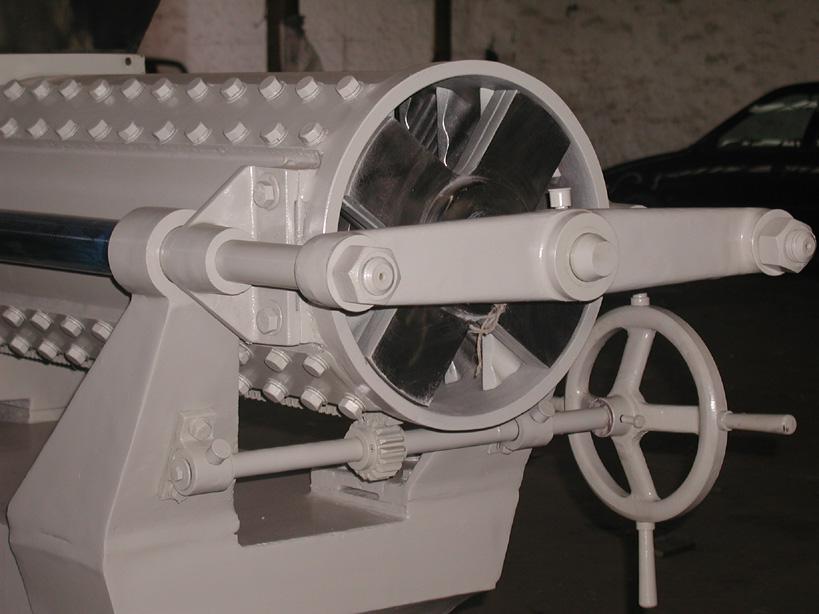

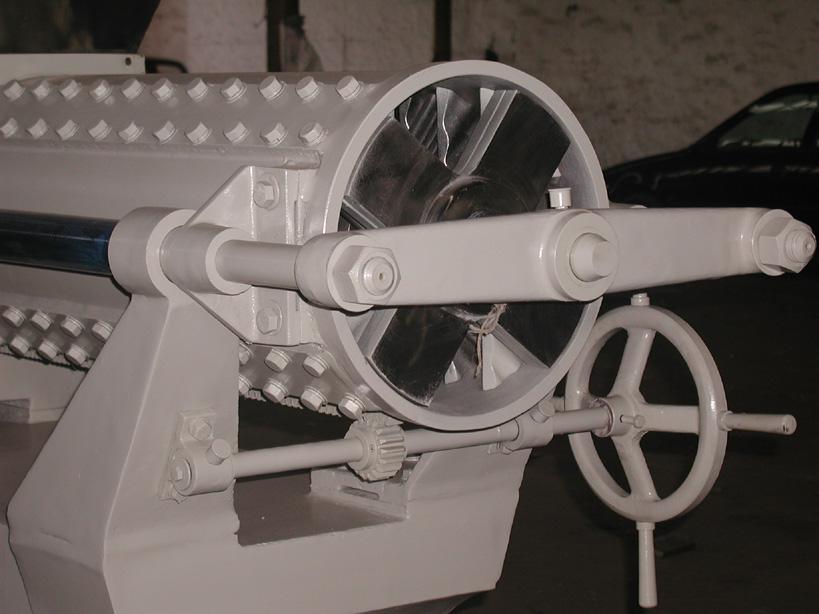

- Main Drive:

- Heavy-duty heli-bevel gearbox with a 30:1 ratio for efficient power transmission and reduced power consumption.

- Coupled with a 4-step pulley offering speeds of 35/40/45/50 RPM, driven by a 20 HP, VFD-compliant motor (1,440 RPM, 50 Hz).

Benefits:

- Enhanced Durability: High-quality materials and construction ensure long-lasting, reliable performance.

- Operational Efficiency: Advanced automation and electro-pneumatic controls streamline the process and improve precision.

- Versatility: Multiple material options and programmable settings cater to a wide range of production requirements.

- Energy Efficiency: The specialized gearbox and motor configuration reduce power consumption, lowering operational costs.

This state-of-the-art orthodox tea roller is a perfect blend of tradition and modern technology, delivering superior tea quality and operational convenience for today’s tea producers.