Brief on customer:

The industry: Tobacco Years of operation: Since 1908 Location: Likoni.

What was the customers problem:

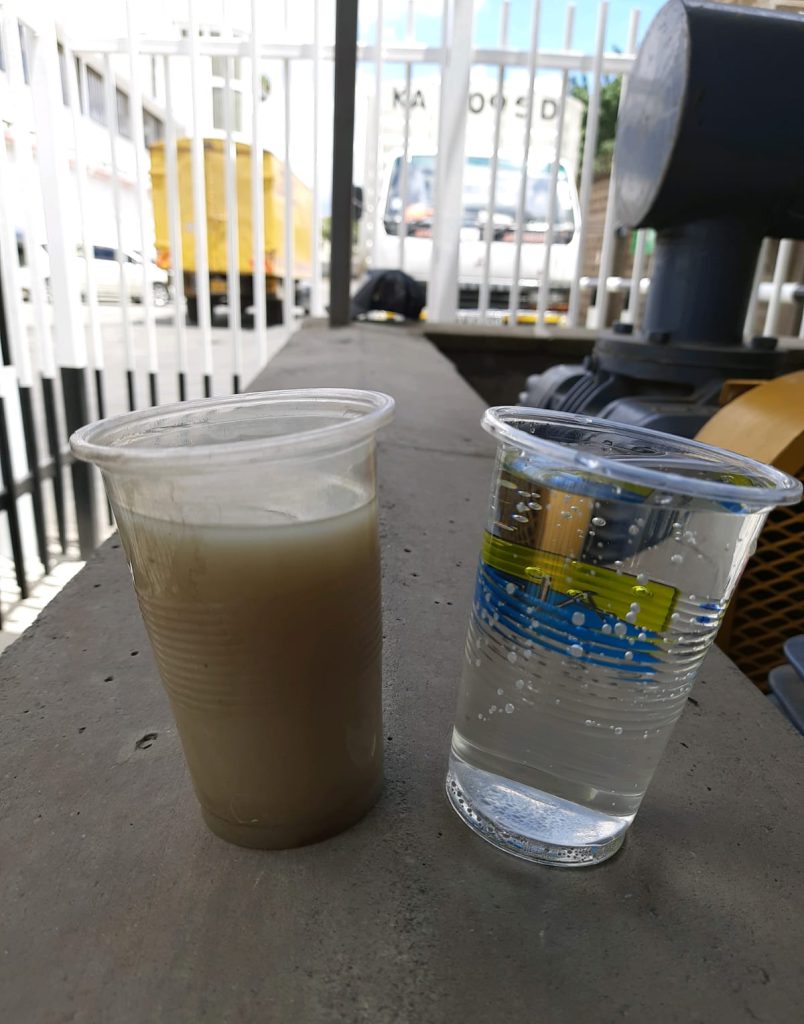

There was a lot of waste water from production, this was heavily polluted and was far from meeting NEMA specifications, meaning that they could not dump it.

Tobacco production can result in high levels of polluted water for a few reasons:

Pesticides and Fertilizers: Tobacco crops are heavily reliant on pesticides and fertilizers to increase yields and protect against pests. These chemicals can leach into the soil and nearby water sources, leading to pollution of the water supply. Additionally, excessive use of fertilizers can cause eutrophication, where nutrients in the water stimulate excessive plant growth, leading to oxygen depletion and harm to aquatic life.

Processing: The processing of tobacco also contributes to water pollution. During the curing process, tobacco leaves are often air-dried using large amounts of wood, which can result in the release of particulate matter and smoke. This can pollute the air, water, and soil in the surrounding area.

Overall, tobacco production can have a significant impact on water quality and the environment, and it’s important to implement sustainable agricultural practices to mitigate these effects

What was Spenomatic solution / offering ?

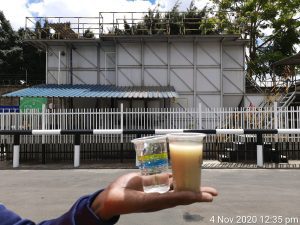

We installed an effluent treatment plant that would 100% recycle the water so that it can be used again for Utility purposes.

- Would the customer recommend the solution to other similar customers?

Yes as this has reduced operating cost due to being able to reuse water, as well as being beneficial to the environment.

- What advantage did the customer notice for choosing Spenomatic over any other provider of similar solutions

We are able to treat complex contaminated water to whatever the customer needs with fully customized solutions.

What’s the result of this;

Benefit to customer

There are several benefits experienced by using recycled water from an effluent treatment plant in tobacco production:

Water conservation: The use of recycled water reduces the demand for freshwater resources, helping to conserve water and reduce water stress in the local area.

Cost savings: Using recycled water can be more cost-effective than using freshwater sources, as the cost of treating and distributing recycled water is often lower than the cost of sourcing and treating freshwater. This has helped to reduce production costs and improve profitability for the customer. The plant has a capacity of treating 48,000 litres per day with savings of USD 1.38 per Metre cubed of treated water.

Increased productivity: Recycled water can contain nutrients that are beneficial for plant growth, which can help to improve tobacco yields and quality. Additionally, using recycled water has helped to maintain a more consistent water supply for crops, which has assisted in reducing stress on plants and improve their overall health.

Compliance with regulations: NEMA regulations require businesses to reduce their water usage and wastewater discharge. Using recycled water can help businesses to comply with these regulations and avoid fines or other penalties.

Overall, using recycled water from an effluent treatment plant can offer a range of benefits for tobacco growers, including cost savings, environmental benefits, and improved productivity. However, it is important to ensure that the recycled water meets the required quality standards and does not pose any risks to human health or the environment.

Environmental / economical impact

Environmental benefits: By using recycled water, our client has reduced the amount of wastewater discharged, which has helped to protect the local ecosystem and reduce the impact of agriculture on water quality. It has also eliminated the need for energy-intensive wastewater treatment processes, which can help to reduce greenhouse gas emissions and mitigate climate change.